The importance of using a quality neutral link connectors for industrial projects.

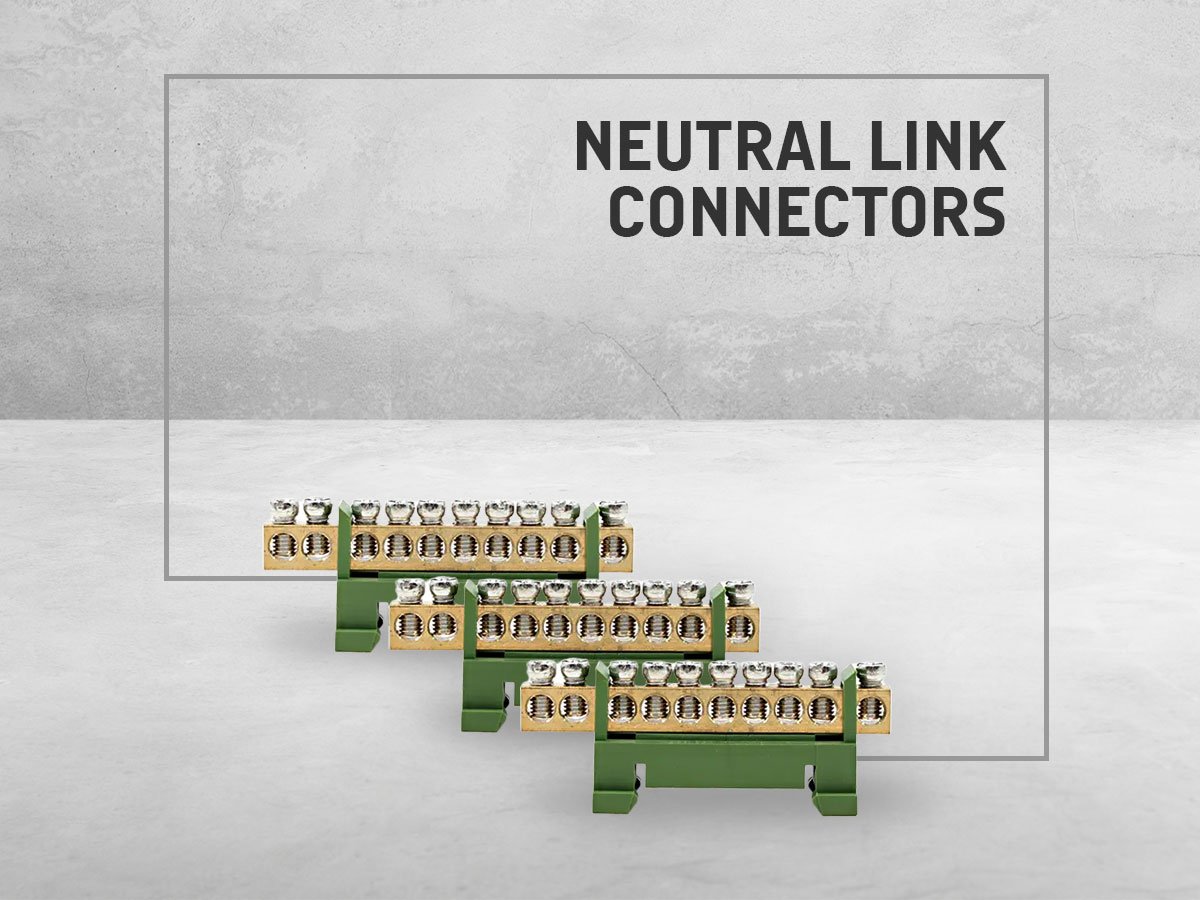

Neutral link connectors are the heart of several industries and play a critical role in every industrial application. In a typical electrical circuit, neutral link connectors are used to terminate neutral wires. In electrical boards and panel boards, it has an important role to play. These can be found in cars, washers, dryers, surge protectors, panel boards, and electrical boards.

How confident are you that your life and home are protected from household dangers caused by malfunctioning electrical systems? In construction, multiple circuit breakers (MCBs) are used, as are residual current devices (RCDs).

The RCD protects your life by preventing electrocution, while the MCB prevents electric fires caused by overheating wires.

The builders also use quality neutral link connectors along with MCB and RCD for circuit protection as it is an important component of the panel boards. However, using premium quality neutral link connectors are more beneficial and cautious.

In this article, let’s first understand

Neutral link connectors have a vital role to play.

Neutral link connectors are recognized as the mainstay in structuring circuit protection like RCD, circuit breaker, and MCB. It is usually used on panel boards that have copper bus bars, brass neutral links, and earth links to allocate current. In every application, it is crucial and important to isolate electric equipment and eliminate faults downstream of switchgear. In addition, it is important to prevent short circuits or damage resulting from overload with circuit breakers. While neutral links and terminal blocks serve different purposes, they are both unique.

There is a wide range of neutral link connectors available in the market, but some of them are useful for the required applications. These connectors are available in various specifications such as size, shape, holes, thread, head type, lock type, length, material, coating, and tensile strength. All of these neutral link connectors offer the best performance based on their working aspects.

A neutral link connector is one of the most used electrical connectors for different purposes in industries. So, if you are looking to get a quality neutral link connector for you, then there are some factors including dimensional specification, types, features, characteristics, performance, electrical and mechanical strength, and many more that you need to consider before buying them.

Different Industries Rely on Different Neutral Link Connectors:

In this technology-driven market, every new invention or new product requires a special and unique solution. And as per different industries, it should be different and reliable. To meet various neutral link connectors’ industrial requirements and applications, the neutral link connectors manufacturers work as a great source of obtaining the best suitable solution for custom industrial neutral link connectors. Neutral link connectors are quite a in demand and their crucial component is used in main industries like electronics, electrical, aerospace, construction, medical, military, automobile, Defense, marine, and telecommunication.

Why Quality Neutral Link connectors?

Quality is the utmost requirement in any industrial application. When it comes to neutral link connectors, the manufacturer of neutral link connectors uses high-quality metal material and composition to ensure the overall quality of neutral link connectors. Free-cutting brass IS 319 Type (I) or BS 249 Type (I) is most widely used for manufacturing neutral link connectors because of their characteristics, and advantages. It is an alloy of different metals that provides special attributes like conductivity, strength, crack resistance, and corrosion resistance. These qualities add to the reliability and durability of neutral link connectors. Some other materials such as copper, bronze, aluminium, stainless steel, and steel, are also used for neutral link connectors as per industrial requirements. Depending on your needs, they are available in nickel-plated, natural, tin-plated, silver or gold-plated, anti-rust coatings, and PVC coatings to give extra strength and improve service life.

The Advantages of using quality Neutral Link Connectors:

- Protection against electrical shocks: Neutral link connectors help to protect against electrical shock by providing a safe path for electrical currents to flow.

- Require less maintenance or maintenance-free:Electrical systems and installations require regular maintenance and upkeep to ensure they are functioning properly. High-quality neutral link connectors can be beneficial for time-consuming and costly projects.

- Improved power quality:Neutral link connectors help to improve the power quality of an electrical system by reducing voltage imbalances and minimizing the risk of power outages.

- Enhanced equipment performance:Neutral link connectors help to enhance the performance of electrical equipment by reducing the risk of damage from electrical surges and lightning strikes.

- Increased safety for sensitive equipment: Neutral link connectors helps to ensure the safety of sensitive equipment, such as computers and medical devices, by protecting them from electrical interference.

- Compliance with safety regulations:Neutral link connectors are a crucial aspect of electrical safety and are often required by local and international safety regulations. It helps to ensure that an electrical system is designed, installed, and maintained to the highest standards of safety.

- Flexible and easy to install:The Neutral link connector contains many holes and options for neutral wiring, which makes it easy to install and maintain the system.

There are such wide varieties of neutral link connectors in the market which makes it difficult to choose the right and quality neutral link connector for an individual who is not dealing with them constantly. Therefore, choosing an experienced and ISO-certified neutral link connector manufacturer like Teron Metal Components will help to minimize your effort and you will be able to guarantee your service’s reliability. If you have a related query, feel free to contact us. Also, kindly share your special requirements if you are looking for high-quality custom neutral link connectors.