How are stainless steel neutral links different from brass neutral links?

Are you looking for neutral links? There are many types of neutral links that are used in a variety of industrial applications. For optimal performance, you must use suitable type of neutral links. A wrong choice may either alter the functionality of your application or even create any risk eventually. The neutral link selection process will be more challenging when it comes to the material, style, and price! It is not just about how aesthetically pleasing the neutral link is, but also about its quality and durability. An industrial application of any size or type requires quality neutral links. Brass and stainless steel are the two main types of materials used for electrical components. Both options are highly beneficial and ensure great functionality, but what is the difference between them when it comes to neutral links?

Let’s begin by understanding what a brass neutral link and a stainless steel neutral link are.

Brass Neutral Links:

Brass neutral links are manufactured from a combination of alloys made primarily of copper and zinc. Depending on how much of each metal is present in the mixture, brass neutral links will have different colors and qualities. Solid brass neutral links are highly durable and reliable due to their ideal balance of robustness and flexibility. Copper is used in brass neutral links, so they have excellent thermal conductivity. When it comes to electrical and thermal conductivity, brass neutral links outmatches stainless steel neutral links by fifteen times. Brass neutral links are the most used type of brass electrical components for conveying hot or cold water within industrial or residential systems and for petroleum products. This is because of their high anti-corrosive properties. Brass neutral links’ tensile strength exceeds carbon steel.

Advantages of Brass Neutral Links

- Brass neutral links are strong, even surpassing low carbon steel tensile strength.

- Neutral links made from brass are suitable for cold as well as hot water installations, including potable water transport systems.

- It is common to be exposed to moderate and alkaline solutions, while strong solutions such as cyanides and hydroxides are avoided.

Stainless steel Neutral Links:

Stainless steel neutral links are manufactured from an alloy combination of iron, carbon, and chromium that provides a smooth, and easy-to-clean surface. Stainless steel is extremely sanitary and suitable for hospitals, pharmaceutical industries, food factories, construction, and related industrial applications. Stainless steel neutral links have excellent mechanical strength. Due to its heat-resistance, corrosion-resistance, tarnish-resistance, and rust-resistance properties, it requires less maintenance and lasts longer. Stainless steel neutral links made from super austenitic stainless steel (UNS S31254 or N08367), super duplex stainless steel (S32760 or S32750), and low-carbon grade stainless steel 316L are used in the marine, desert, and in locations with high rainfalls.

Advantages of Stainless steel neutral links

- Acid and petroleum compounds are not a problem for stainless steel neutral links.

- They are resistant to nitric acid and ether citric solutions, but not to hydrochloric acids.

- Their exact comparisons are determined by the metal and grades.

- They offer services at a greater temperature.

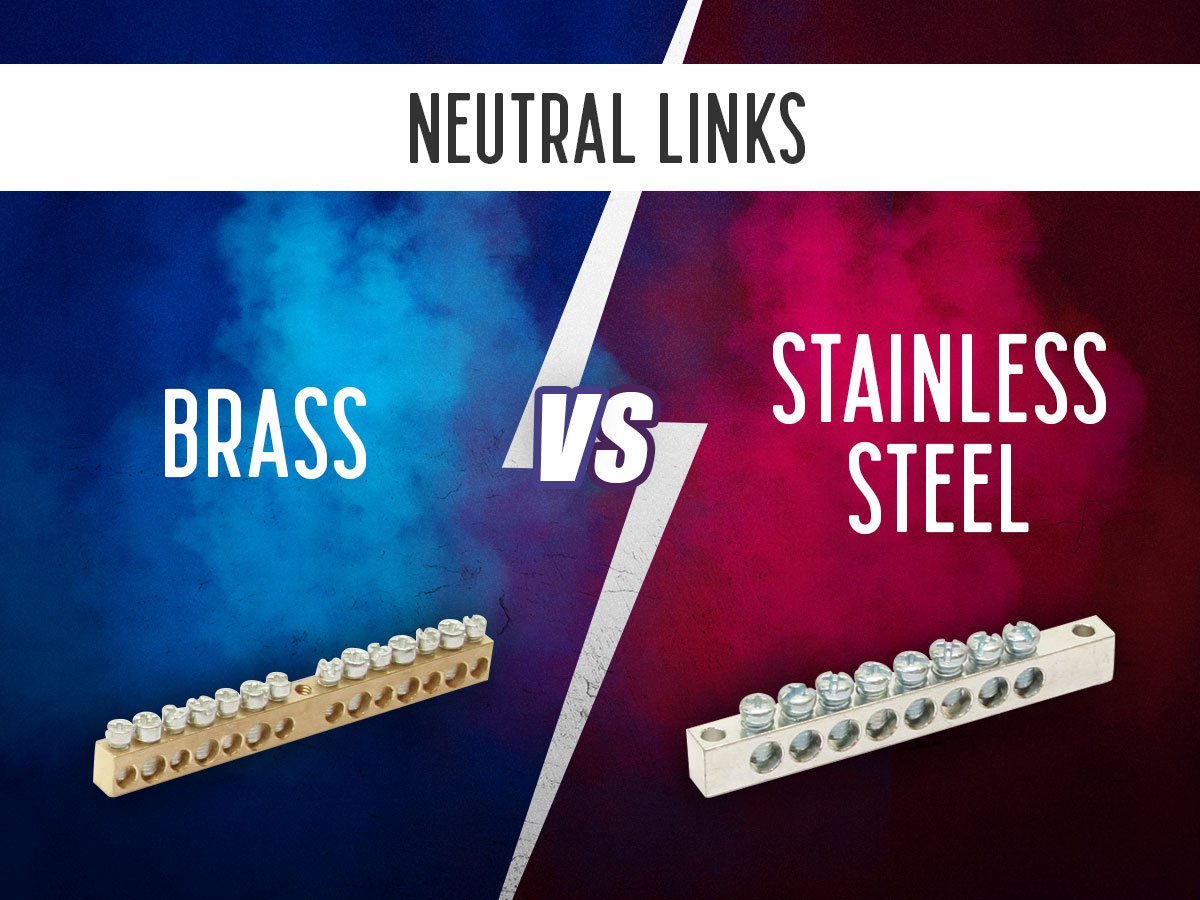

Comparision between Brass Neutral Links and Stainless steel Neutral Links:

| Brass Neutral Links | Stainless steel Neutral Links |

| Brass neutral link can withstand corrosion better. | Stainless steel is the best in the corrosion resistance. |

| Much better for welding compared to stainless steel neutral link. | Stainless steel neutral links must be frequently broken down if they are to be used for welding. |

| Ideal for high conductive electrical applications. | The best options for high pressure and temperature situations. |

| Easy to manufacture due to soft and easy too cast material. | Comparatively difficult to cast and machine due to its material hardness. |

| Based on different brass grades it can be silver, grey, brown, gold, or orange. | There are shades of Gray or silver in it. |

| Brass neutral link is less durable against flowing water, because it is softer. | In rushing water, stainless steel neutral link will endure longer. |

| The cost of brass neutral link is depending on the brass grade or alloy you select. But generally low in cost. | The cost of manufacturing stainless steel is expensive. |

| It contains small amounts of lead | It does not contain lead. Its 100% lead-free. |

In conclusion, both brass neutral links and stainless steel neutral links have many benefits. In terms of general utility, brass neutral links are mostly considered and most suitable for general applications. There are many advantages and differences between brass and stainless steel neutral links, so it’s important to understand their properties, advantages, and differences before making a decision. The detailed information will help you determine which is more valuable for their specific applications.

If you looking to buy standard or custom neutral links, Teron Metal Components is a high-quality neutral link manufacturer and exporter you can trust. No matter whether your requirement is low, medium, or high-volume, or if you are looking for contract or OEM manufacturing of neutral links, request a free quote or contact us via e-mail at sales@teronmetalcomponents.com. We are happy to hear from you!