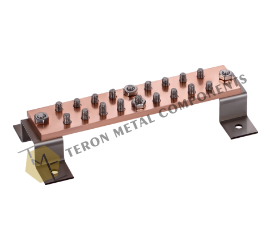

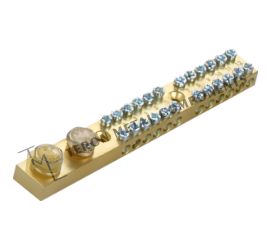

Teron Metal Components is a prominent manufacturer and exporter of terminal bars. Our offered range of terminal bars includes brass terminal bars, 1-meter terminal bars, neutral terminal bars, earthing terminal bars, regular-duty terminal bars, heavy-duty terminal bars, and many more. With the help of our distinguished professionals, we have been able to bring forth quality-approved terminal bars. Our offered range of terminal bars is appreciated by clients for its dimensional stability and corrosion resistance. Furthermore, we customize these terminal bars keeping in mind the variegated requirements of customers at industry-leading rates.

At Teron Metal Components, we rely on the search for excellence as a continuous process and our achievements are purely milestones in the long journey. These terminal bars are manufactured under the guidance of our adept professionals who make use of premium grade materials and technology in the manufacturing process. Further, we follow international standards while manufacturing these terminal bars to meet the preferred needs of the customers. Our offered machined components find their application in various industries, and we also provide customization as per client specifications.

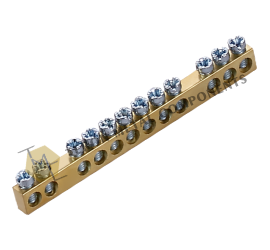

Terminal bars are very crucial components in every application due to its nature. Electrical terminal bars play a significant role in isolation of electric equipment & clearing faulty downstream, by means of switchgear and preventing short circuits & protecting the electric circuit from damage caused by overload, in the form of circuit breaker & so on terminal bars are used as an accessory in panel boards & electrical board in industries like electrical, electronics & telecommunications. Terminal bars are considered as a backbone in building circuit protections such as MCB, switchgear, circuit breaker, RCD, etc. Terminal bars are ideal to facilitate the effective distribution of current.

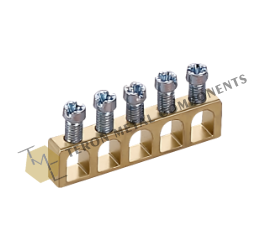

Terminal Bars Specifications

- Wide utility and optimum finish

- Superior and appreciable functionality

- Thread as per international go and not go gauge standard

- Deep Groove for maximum Pull out Resistance

- Inner Diameter after threading with very close tolerance to prevent unrequired flush to enter

- Pay major role in Isolation